Project(s) Overview

Mechanical Design Engineering Internship

During my internship at StrongBo AgTech, I contributed to a variety of projects critical to the company’s product development. As a small start-up, StrongBo offered an environment where every task carried significant impact, which challenged me to adapt quickly and take ownership of diverse responsibilities. This experience allowed me to strengthen my technical skills while gaining exposure to multiple areas of mechanical engineering.

Key areas of work included:

-

Part & Assembly Design – Developing and refining CAD models for production.

-

Coding & Statistical Analysis – Writing Python programs to analyze customer and machine usage data.

-

Quality Assurance & Testing – Conducting design validation and troubleshooting to improve reliability.

-

Portability & Ergonomic Design – Redesigning mechanisms to make machines foldable and transportable.

-

R&D Reporting – Preparing technical documentation to support SR&ED innovation claims.

-

Engineering Drawings – Creating detailed drawings for manufacturing and assembly.

About StrongBo

WatArrow Plane Before I Joined

1

StrongBo AgriTech is a nimble, under-10-person startup building sophisticated automated livestock weighing systems—called Auto-Weighers—entirely in-house.

2

The Auto Weigher operates simply but smartly: farmers deploy the unit in the field, place an attractant like a salt or molasses block, and let the animal step onto the platform. An integrated EID reader identifies the animal, while an internal algorithm estimates its full body weight from a partial front-foot measurement

3

Even at its small size, StrongBo has made a significant mark, securing a €750,000 seed funding round to support product commercialization—backed by globally recognized partners like Gallagher, Enterprise Ireland, and Canadian agricultural investors

Project 1: Assembly Restructuring/Part Design

Solution Generation

One of the first major projects I tackled at StrongBo was a complete restructuring of our SolidWorks assembly hierarchy. At the time, our models didn’t match how the machines were built on the shop floor—making BOMs confusing, inventory hard to manage, and customer support slower than it should’ve been. Because StrongBo is a small start-up, fixing this became company-critical.

Key steps I took:

-

Renaming convention – Created 6 part/assembly categories (sheet metal, tube laser, standard parts, off-the-shelf, welded, bolted). Built a Google Sheets cross-reference of old vs. new names and batch-renamed files using Pack & Go. → Result: instant traceability and faster troubleshooting when customer issues came in.

-

Engineering drawings – Created 100+ part drawings and 20 sub-assembly drawings with a new standardized template.

-

Sheet metal: 3-sheet system (orthographic views, flat pattern w/ bend details, 1:1 DXF sheet automated via Task Scheduler).

-

Tube/standard parts: simplified 1-sheet drawings with dimensions.

-

Assemblies: exploded views + special notes (e.g., pivot bolts).

-

-

Rebuilt assemblies from scratch – Instead of patching broken mates, I rebuilt sub-assemblies and the top-level assembly using smarter mating strategies for scalability and change tolerance.

-

New part design – Designed reinforced plates and other components to solve structural failures and add fold-down portability features.

Results:

-

Clearer, more reliable documentation for manufacturers.

-

BOMs that matched reality, simplifying inventory management.

-

Robust, scalable assemblies that can evolve as StrongBo grows.

Part Naming Convention

Sheet Metal Part That I Designed

Second Sheet: Bend Lines + Flat Pattern

First Sheet: 3 Views + Isometric

Third Sheet: Easy To Save DXF

Restructured Assembly Hierarchy

Old Assembly Hierarchy

Project 2: Battery Life Prediction Code

Solution Generation

One of the recurring challenges for StrongBo’s customers was the sudden failure of machine batteries in the field. When a unit shut down unexpectedly, farmers could lose weeks of livestock weight data until the battery was replaced. To solve this, I developed a Python program in Jupyter Notebook that analyzed machine telemetry and predicted when a battery was likely to fail.

The dataset consisted of hourly data packets from approximately 100 deployed machines. Even when narrowed to a single customer, this represented more than 4,500 data points over six months. The raw voltage readings were noisy and difficult to interpret, so I created a processing and analysis workflow that transformed the data into actionable predictions.

Key methods developed:

-

Data reduction and smoothing

-

Aggregated hourly data into daily averages, reducing the dataset size by over 90% while retaining useful trends.

-

Tested moving averages and filtering to reduce voltage fluctuations.

-

-

Automated detection of battery replacements

-

Wrote a script to detect voltage “jumps” above a set threshold (e.g., +1.5 V) and classify these as new battery events.

-

This enabled the segmentation of the dataset into distinct discharge cycles.

-

-

Cycle segmentation and decay analysis

-

Separated each discharge cycle and calculated the decay slope (volts per day) using linear regression.

-

Built histograms of decay rates to identify typical lifespans and outliers.

-

-

Visualization and validation tools

-

Generated graphs of voltage over time with automated annotations marking battery swaps.

-

Created cycle-by-cycle plots to validate the regression models and identify anomalies in charging patterns.

-

The tool produced clear insights into how long batteries lasted under real-world operating conditions and allowed StrongBo to deliver predictive battery life estimates directly to customers.

Results and impact:

-

StrongBo’s software team incorporated this tool into the customer-facing app, enabling proactive battery replacements.

-

Farmers gained the ability to plan maintenance rather than react to machine failures, avoiding gaps in livestock data.

-

The tool worked best on non-solar machines, but exploratory filtering of nighttime-only data showed promise for adapting the method to solar-powered units.

This project combined data engineering, statistical modeling, and visualization, and provided StrongBo with a valuable predictive capability that directly improved customer experience.

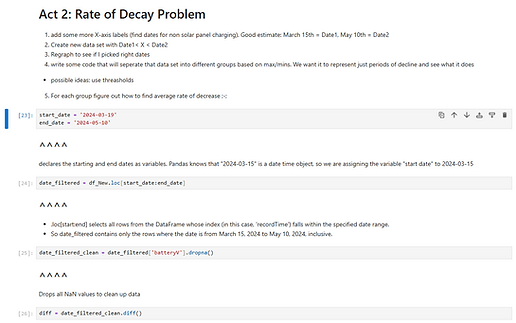

Part 1: Filtering For One Customer

Part 2: Graphing Raw Data

Part 3: Finding Battery Changes

Part 4: Graphing Battery Changes

Part 5: Reducing Data Set Further

Part 6: Linear Regression - Finding Rate of Decay

Final Histogram of Rates of Decay

Experimenting With Solar Panel Units

Project 3: Portability Design

Solution Generation

One of StrongBo’s biggest challenges was shipping its auto-weighers to customers. The machines were bulky in their deployed form, difficult to stack, and frequently arrived damaged after transport. This made shipping expensive and inefficient, since we were paying for wasted container space while still risking damage claims.

My task was to redesign key parts of the machine to make the system portable and stackable, while ensuring customers could still assemble the product with minimal effort once it arrived.

Design solutions I developed:

-

Folding trough system

-

Redesigned the trough mount to include a slotted feature (instead of a fixed bolt) so it could fold downward, reducing machine height in transport.

-

-

Collapsible side gates

-

Created new gate designs with a locking plate mechanism, allowing them to be folded inward for shipping or outward for deployment.

-

-

Redesigned connector plate

-

Completely re-engineered the sheet metal plate that joined the weighing platform to the main body.

-

Added bolt holes that doubled as a pivot axis, enabling the entire machine to fold down flat for stacking.

-

This single change solved both a structural failure issue and portability, making it a pivotal design improvement.

-

-

Space optimization

-

Proposed relocating wheels and stub axles to unused space at the back of the machine.

-

Designed transport configurations where the tow bar could be strapped to the side, minimizing horizontal pallet footprint.

-

Challenges and decisions:

-

Learned advanced SolidWorks sheet metal features to meet strength, manufacturability, and cost constraints.

-

Balanced portability with ease-of-assembly so customers wouldn’t need to rebuild machines upon delivery.

-

Iterated through multiple design concepts, evaluating trade-offs between strength, weight, and part complexity.

Results and impact:

-

Reduced machine footprint to fit on a 40 × 48 inch pallet.

-

Enabled up to 48 units per standard 40-ft shipping container (nearly triple previous capacity).

-

Dramatically cut shipping costs while increasing order fulfillment capacity.

-

Reduced in-transit damage by allowing machines to ship in a folded, stackable configuration.

This project combined mechanical design, sheet metal engineering, and logistics considerations, and the results had a direct financial impact on StrongBo’s operations.

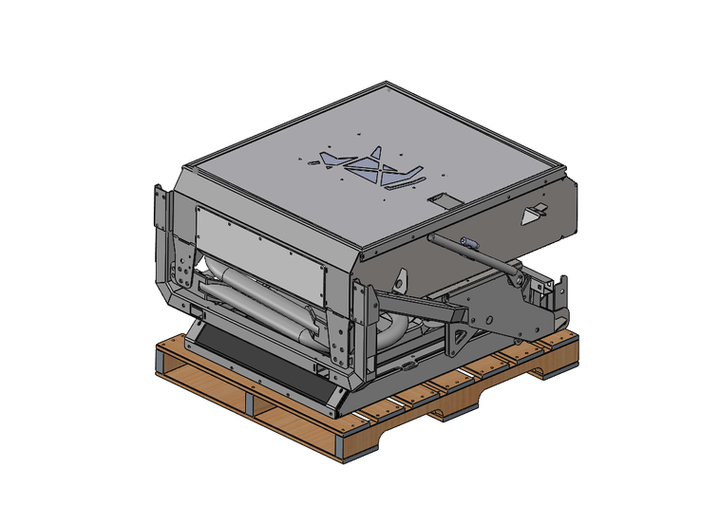

1: Deployed Auto-Weigher

2: Remove Wheels & Towbar

4: Remove Solar Panel Arm Bolts & Fold Down

3: Fold Side Gates Inward & Push Down Trough

5: Fold Main Body Downward, Ready To Be Shipped!

Results

Working at StrongBo was an extremely valuable experience to me. I felt like everything I did had purpose, and often times (based on what I've heard from other students) a lot of interns feel unfulfilled in their positions, because they feel as though the work they are doing is insignificant. StrongBo was a rare opportunity which allowed me to not only grow as an engineer, but an employee as well. Aside from all the technical skills I picked up, I learned things like how to communicate clearly and concisely. Because of how busy everyone was due to the size of the company, I had to adapt to a fast-paced work environment where people need important information in the least amount of time possible. I was grateful to have had the chance to really experience my first engineering job! Some results from this internship were:

-

Learned to use SolidWorks Sheet Metal

-

Strengthened SolidWorks assembly structuring and file organization

-

Improved mechanical part and assembly design skills

-

Gained experience with design for portability and ergonomics

-

Improved ability to balance cost, strength, and manufacturability in design

-

Learned fundamentals of design for manufacturing (DFM) and design for assembly (DFA)

-

Gained experience with engineering drawings and documentation

-

Improved concise and clear communication in a fast-paced environment

-

Strengthened problem-solving under tight deadlines

-

Learned to manage multiple projects simultaneously in a startup setting

-

Improved ability to work across different areas of mechanical engineering (design, testing, R&D, reporting)

-

Gained experience with QA and testing processes

-

Developed coding and statistical analysis skills

-

Learned how to contribute to SR&ED reporting and R&D documentation

Palletized Auto-Weighers